So far, silicone breast implants were primarily used in breast reconstruction following mastectomy. In Japan, the breast implant manufactured by Allergan was the only product approved by the Ministry of Health, Labour and Welfare. In July 2019, however, the U.S. Food and Drug Administration (FDA) requested Allergan to recall its breast implants due to risk of breast implant-associated anaplastic large cell lymphoma (BIA-ALCL), and their production was discontinued.

Although autologous tissue-based breast reconstruction, in which the patient’s fat cells are collected and injected, has also been performed, the graft survival rate is low and outcomes vary with the patient’s background. Some patients have to undergo several transplant surgeries.

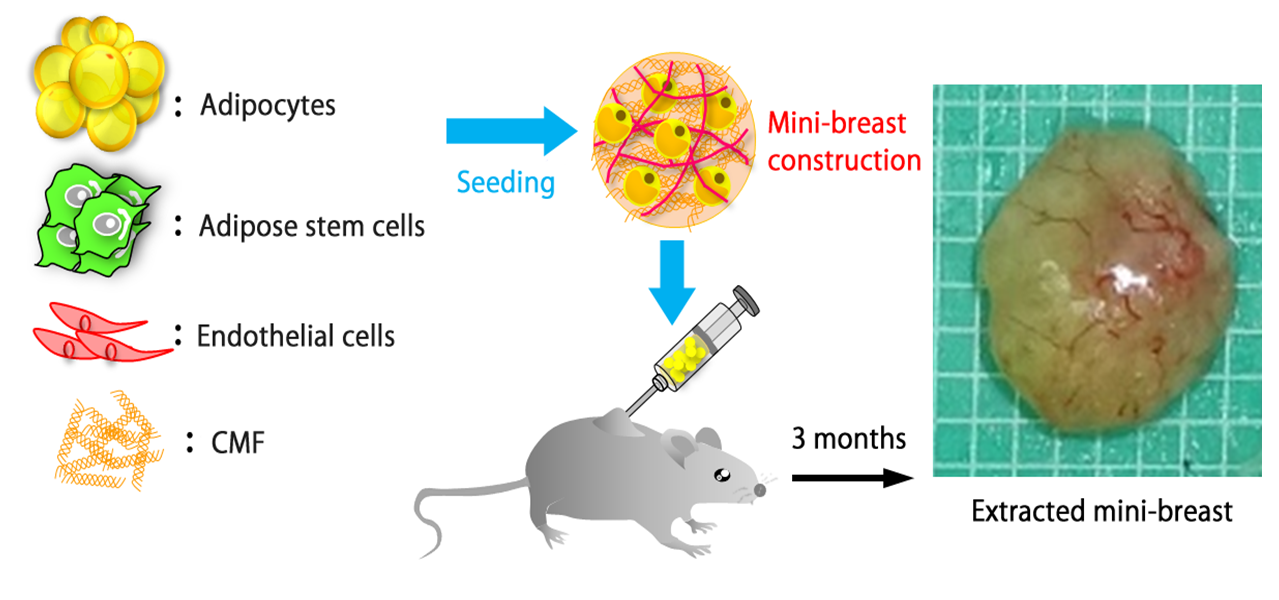

In this study, the research team used type I collagen microfibers (CMFs) and applied their unique tissue engineering technique to the production of mini-breasts. CMFs act as a scaffold for adipocytes, adipose-derived stem cells, and vascular endothelial cells. The fabricated vascular network supplies the cells with nutrients and oxygen, and connection between the mini-breast and the patient’s blood vessels was also established. Transplanting this mini-breast into small animals resulted in a graft survival rate twice as high as that of conventional aspirated fat tissue transplantation.

Since cells derived from patients are used, no inflammatory reaction was observed, indicating that the mini-breasts are highly safe. Furthermore, the volume of the mini-breast to be implanted is adjustable by in vitro culture. “Our findings will lead to a new, highly safe breast regenerative medicine that can replace the conventional fat cell injection and implantation,” says Prof. Matsusaki, who led the study.

The technique used in this study was introduced in “3D collagen microfibers stimulate the functionality of preadipocytes and maintain the phenotype of mature adipocytes for long term cultures,” published in Acta Biomaterialia at DOI: https://doi.org/10.1016/j.actbio.2018.11.048.

Primary keyword: Medicine/Health

Additional keywords: biomedical engineering, biomaterials, regenerative medical engineering, artificial organ science

Title: “3D collagen microfibers stimulate the functionality of preadipocytes and maintain the phenotype of mature adipocytes for long term cultures”

Journal: Acta Biomaterialia

Authors: Fiona Louis, Shiro Kitano, João F. Mano, Michiya Matsusaki

DOI: 10.1016/j.actbio.2018.11.048

Funded by: Japan Science and Technology Agency

About Osaka University

Osaka University was founded in 1931 as one of the seven imperial universities of Japan and now has expanded to one of Japan's leading comprehensive universities. The University has now embarked on open research revolution from a position as Japan's most innovative university and among the most innovative institutions in the world according to Reuters 2015 Top 100 Innovative Universities and the Nature Index Innovation 2017. The university's ability to innovate from the stage of fundamental research through the creation of useful technology with economic impact stems from its broad disciplinary spectrum.

Website: https://resou.osaka-u.ac.jp/en/top

About Toppan

Toppan is a leading global provider of integrated solutions in the fields of printing, communications, security, packaging, décor materials, and electronics. Serving customers in every sector of business and industry, Toppan’s global team of more than 50,000 employees offers optimal solutions enabled by industry-leading expertise and technologies to address the diverse challenges that businesses and society face in today’s rapidly changing market.

For more information, visit https://www.toppan.com/en/ or follow Toppan on LinkedIn https://www.linkedin.com/company/toppan-printing/.