Mono-material barrier package is the future of our sustainable society

The era of mono-material recycling has arrived, and flexible packaging is here to stay.

Plastics - Essential for Life

Plastics are indispensable to our daily life, such as packaging for food and daily necessities and plastic bottles. It is said that mass production of plastics began as a result of WWII due to a shortage of metals and an increase in demand for plastics as a substitute. Plastics, which are light, cost-effective, and have excellent durability and processing capabilities, have continued to expand since then, and film packages using plastics (flexible packaging) have become indispensable for everyday life.

On the other hand, the marine plastics problem has triggered efforts to "de-plastics" worldwide, such as the government and corporations formulating plastics reduction targets.

Imagine, if plastic disappears from our daily lives? For example, imagine a convenience store without plastics, the packaging is difficult to protect food and other contents from the external environment, and conservativeness deteriorates, making it impossible for many products to be placed in stores. Beverages and prepared foods in plastic bottles and plastic containers, as well as rice balls, bread, and confectionery in plastic film packages, will disappear, from convenience stores. In order for us to continue to lead comfortable and convenient lives, we must strike a balance between a "world with plastic" and a "sustainable society."

Without plastic, In-store products such as (left photo) would no longer be available (right photo)

"Recycling" is an important keyword in the use of plastics

In order to aim for a sustainable society while using highly convenient plastics, we are required to establish "recycling" that effectively uses limited resources as well as to reduce and reuse plastic products.

For example, in Japan, plastic bottles are collected and processed into flakes and pellets through a process of sorting, pulverizing, and cleaning, and then transformed into recycled plastic bottles, fibers, plastic molded products, and other recycled products. On the other hand, flexible packaging is no longer reborn as a package once again after use, and many of it is incinerated and used as energy.

Why can plastic bottles manufactured of the same "plastics" be recycled and reused as recycled plastic bottles, but flexible packaging cannot be recycled in the same manner? One of the main reasons is that many flexible packaging products are made up of many materials (multi-material), making it difficult to separate when recycling.

Multi-materials (multiple materials) and mono-materials (single material)

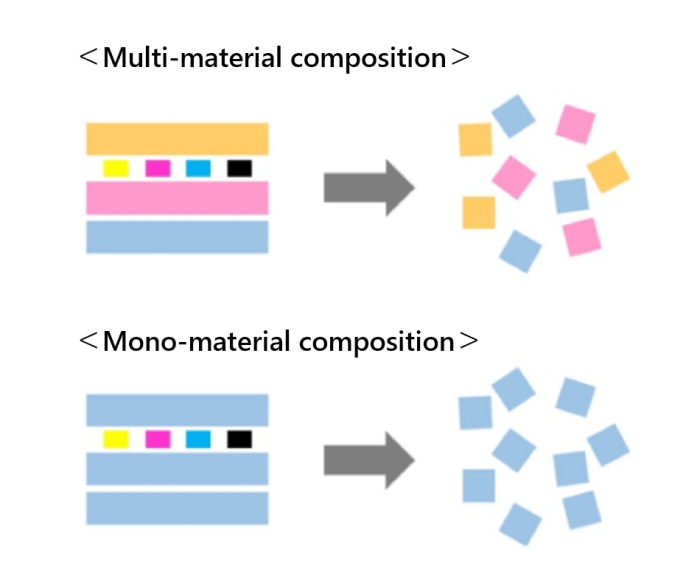

The majority of flexible packaging is made up of numerous materials (multi-materials), each of which serves a distinct purpose. A single film is provided with functionalities such as barrier qualities to increase the preservation of contents by mixing multiple materials. Packages made of a single material (mono-material) are believed to be easier to recycle because each material does not need to be separated for recycling.

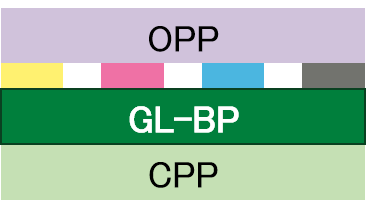

Multi-material configuration: Specifications for packaging made of multiple materials: Difficult to separate various materials before they are labeled as recyclable.

Mono-material configuration: Specifications for packaging made of a single material: There is no need to separate each type of material.

PET bottles are plastic bottles that are manufactured entirely of a single substance (polyethylene terephthalate). As a result, they don't need to be separated or sorted, and they can be molded and recycled into new plastic bottles by melting old plastic bottles.

Flexible packaging, on the other hand, frequently includes numerous materials (multi-materials), and existing technologies make it impossible to separate and filter multi-material plastic films for recycling. Methods for melting and separating packages using solvents and catalysts have been studied, but they have not yet been put to practical use.

Technical Challenges for Mono-material Packaging

Most companies are more active than ever in their efforts to realize a sustainable society today, and expectations for mono-material packaging are increasing. But why is mono-material packaging still not common?

Multi-material packages combine multiple materials with different functions to satisfy the requirement for the intended contents and applications. For example, the film commonly used in conventional retort pouches is composed of four materials: PET, aluminum foil, polyamide (PA), and polypropylene (PP), with PET providing heat resistance and printability, aluminum foil providing oxygen and water vapor barrier properties and light-shielding, polyamide (PA) providing penetration resistance, and PP providing sealing properties, and heat resistance. Thus, in multi-material packaging, the combination of each material provides the necessary functions for packaging.

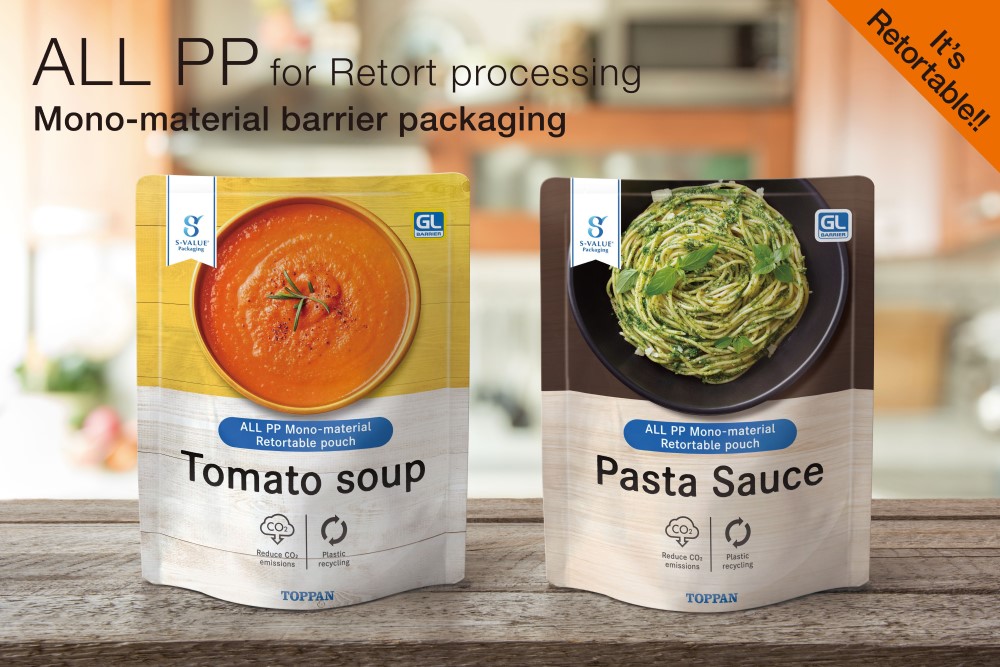

Mono-material packages, on the other hand, are made up of just one material, and the technical difficulty is to satisfy all of the package's functions with just one material. TOPPAN is working on a mono-material barrier package that can perform a variety of tasks in addition to the barrier property, which is the most challenging to achieve in a mono-material package.

TOPPAN's Commitment to Mono-material Barrier Packaging

TOPPAN is committed to the development and manufacture of mono-material barrier packaging on the strength of its extensive experience in developing and marketing packaging materials as one of the world's leading converters and its GL BARRIER, a transparent vapor deposited barrier film with the world's top share of the barrier film market. TOPPAN develops and manufactures GL BARRIER product lineups, which combines proprietary barrier technology with various olefinic film base materials such as PET, PE (polyethylene), and PP, and by combining this barrier film with sealant materials made from the same material, TOPPAN is able to provide a variety of mono-material packages that combine barrier and environmental properties suitable for all applications. By combining this barrier film with sealant materials of the same material, we are able to offer a variety of stand-alone packages that combine barrier and environmental characteristics suitable for all applications.

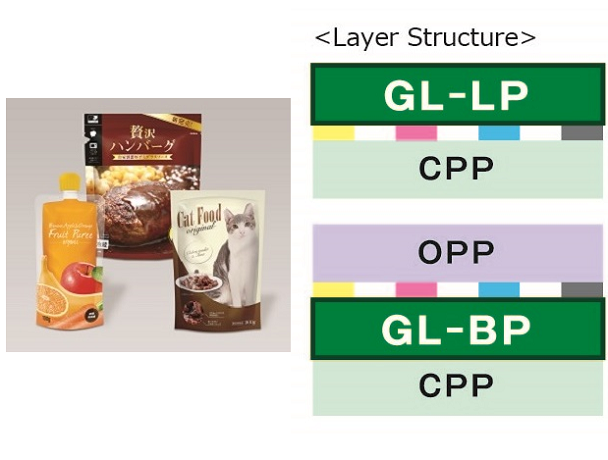

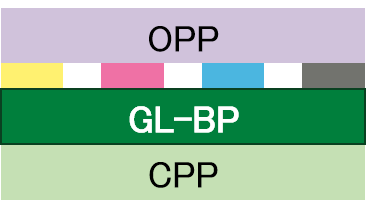

PP mono-material barrier packages are barrier packages consisting solely of film and molded parts made of PP material. GL BARRIER lineups two grades, GL-LP (for dry content applications) and GL-BP (for liquid applications and hot filling).

Mono-material prototype packages using GL-BP has been evaluated as one of the best recyclable packaging products available in Europe by Interseroh+ GmbH and Institute cyclos-HTP GmbH, two German institutions that evaluate recyclability. (Link to news release)

PP mono-material barrier package layer composition

Evaluated as Very Good by Interseroh+ (left)

Evaluation performed on laminated tube with mono-material polypropylene (PP) composition using GL-BP

95% evaluation by cyclos-HTP (right)

Evaluated with a pouch made of PP mono-material

PE mono-material barrier packages are consisting solely of PE material films (and molded parts). The grades of GL-LE (for dry content applications) are compatible with general-purpose packaging such as food.

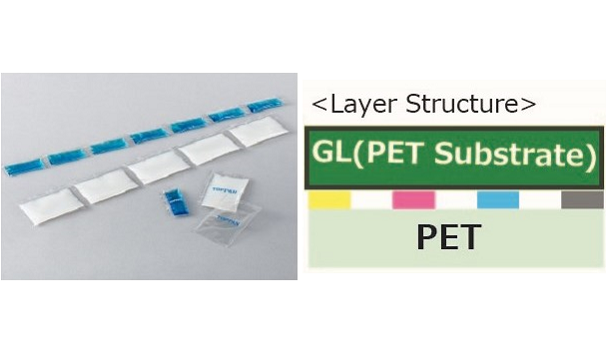

PET mono-material barrier packages are barrier packages consisting solely of PET material film, and are available in grades such as GL-AE (for dry contents) and GL-AR-NF (for boil-and-retort applications), and are also available in light-shielding specifications and grades using recycled materials. It can be used for individual packaging applications such as shampoo, conditioner, and face masks.

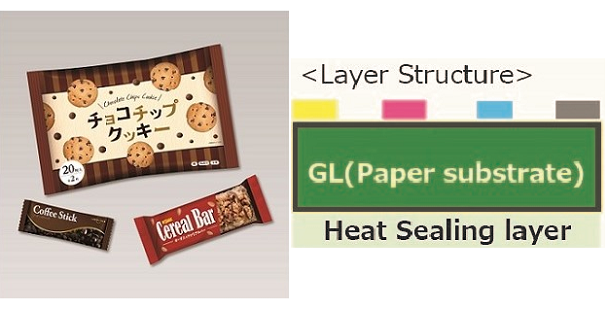

The GL-X-P mono-material barrier package (for dry contents), which uses paper as the base material, is also under development. This development product is designed to be heat sealable, making it possible to realize a package consisting of a single piece of paper. It can be used for food packaging (dry contents), powder standing pouches, and stick packaging.

TOPPAN will continue to develop and manufacture films for different mono-material packaging applications and aiming increase the number of sustainable packaging options, including the use of recycled materials as well. TOPPAN also works to establish recycling schemes and contribute to realizing a sustainable society.