Tokyo –April 28, 2020 – Toppan Printing (Toppan) (TSE:7911), a global leader in communication, security, packaging, décor materials, and electronics solutions, has improved user-friendliness while reducing resource use to achieve enhanced environmental performance by developing the paper tube-pouch, a new paper-based version of the existing tube-pouch, which is shaped like a tube and easy to squeeze like a pouch. The paper tube-pouch is ideal for use in the food, toiletry, and pharmaceutical sectors, and full-scale sales are scheduled to be launched in Japan in fiscal 2020.

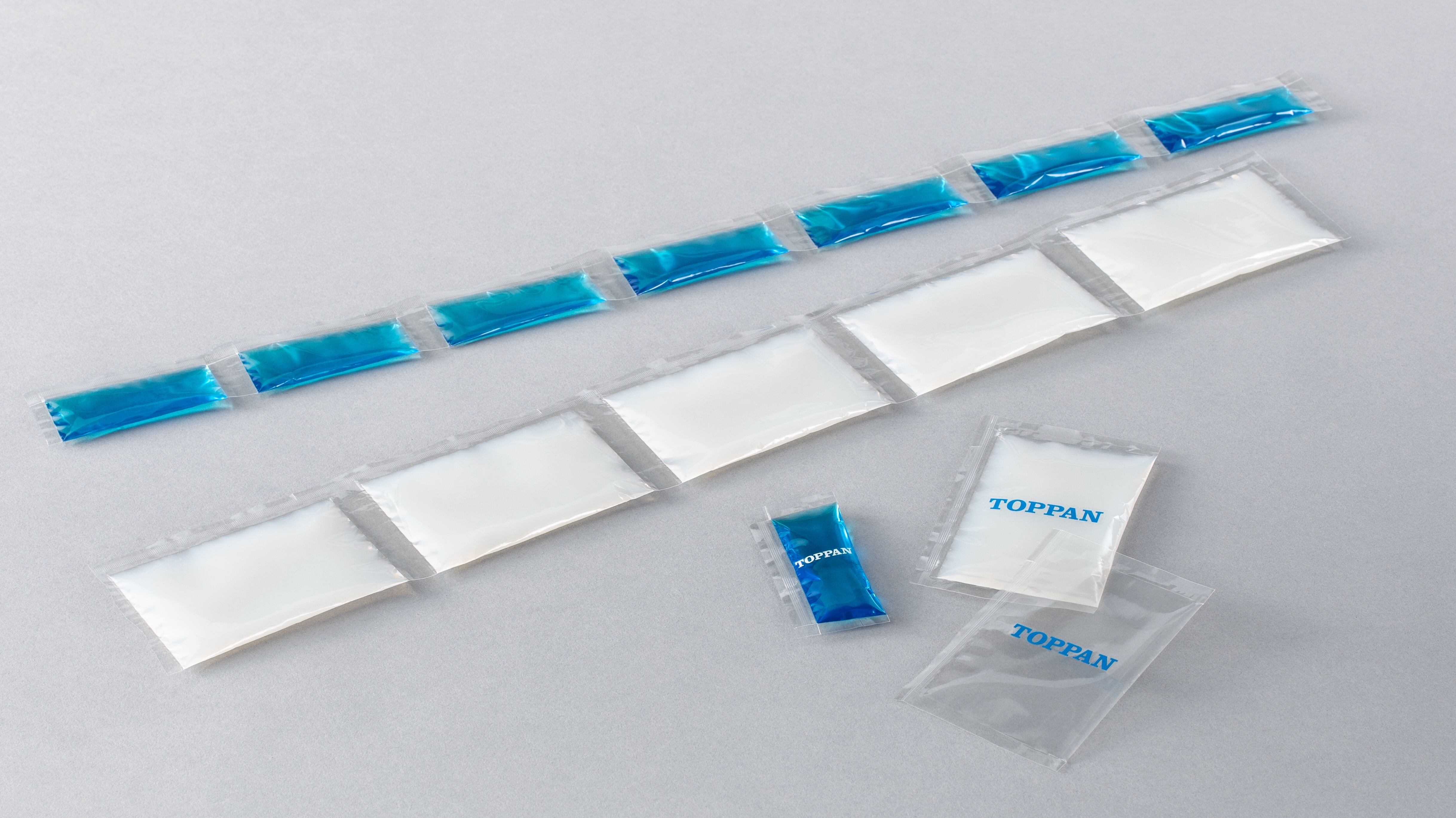

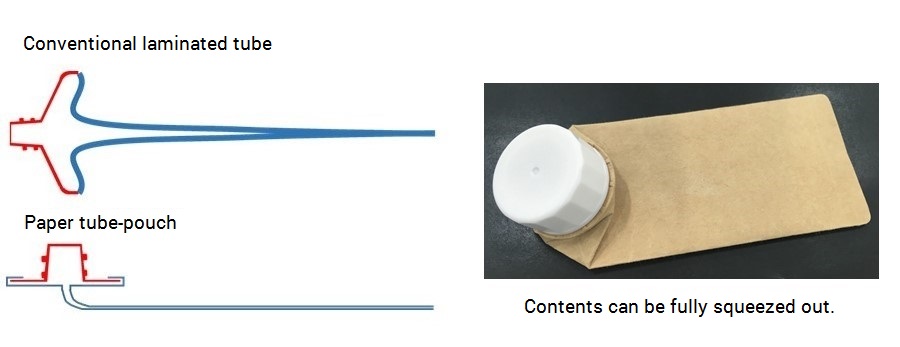

Due to the use of thinner film material, the conventional tube-pouch is easier to squeeze and uses 30% less plastic than the type of laminated tube widely used for toothpaste. The new paper tube-pouch maintains the tube-pouch’s functionality while demonstrating even better environmental performance by employing a paper-based material for the body, making possible a 50% reduction in plastic volume. Coupled with a redesign of the plastic parts of the head section, this enables plastic to be reduced by a total of 65%. Although plastic has been replaced with paper, the tube-pouch still maintains its shape even when the volume of content inside decreases, and the use of Toppan’s proprietary GL BARRIER film on the inner surface ensures the world-class and complete barrier performance required for such items as food and cosmetics.

The body of the paper tube-pouch has a thickness of just 0.1 mm and a special folded structure. Combined with a horizontal design for the plastic spout, this makes it easier to completely squeeze out the contents.

“The paper tube-pouch represents a new solution that can meet the needs of manufacturers, consumers, and society as a whole by reducing impact on the environment, enhancing user-friendliness, and also offering new possibilities for design,” said Shingo Wada, general manager of business strategy in Toppan’s western Japan division. “It is another example of Toppan’s efforts to tackle such issues as marine plastic and the need for efficient circulation of resources by developing eco-friendly packaging and containers that sacrifice nothing in terms of functionality while making use of more sustainable materials, such as recycled and biomass plastics, monomaterials, and paper.”

About GL BARRIER

GL BARRIER is Toppan’s range of transparent films providing world-class barrier performance. The multilayer structure of GL BARRIER films combines unique coating and vapor-deposited layers to enable outstanding, stable barrier performance relied upon for a wide range of items in the food, medical, pharmaceutical, and industrial materials sectors. Films in the GL BARRIER range include PRIME BARRIER, for products with superior functionality and added value, FRESHLIGHT, for simple barrier packaging, and GL FILM, for diverse applications from fast-moving consumer goods to industrial materials.

For more information, visit https://www.toppan.co.jp/living-industry/english/highfunction_energy/barrier_film/

About Toppan

Toppan is a leading global provider of integrated solutions in the fields of printing, communications, security, packaging, décor materials, and electronics. Serving customers in every sector of business and industry, Toppan’s global team of more than 50,000 employees offers optimal solutions enabled by industry-leading expertise and technologies to address the diverse challenges that businesses and society face in today’s rapidly changing market.

For more information, visit https://www.toppan.com/en/ or follow Toppan on LinkedIn https://www.linkedin.com/company/toppan-printing/.