Tokyo – June 20, 2022 –Toppan (TYO: 7911), a global leader in communication, security, packaging, décor materials, and electronics solutions, has developed e-Platch™, an integrated monitoring system that can enhance overall risk management at manufacturing plants by automatically collecting environmental data, such as effluent water level and hydrogen ion concentration.

© Toppan Inc.

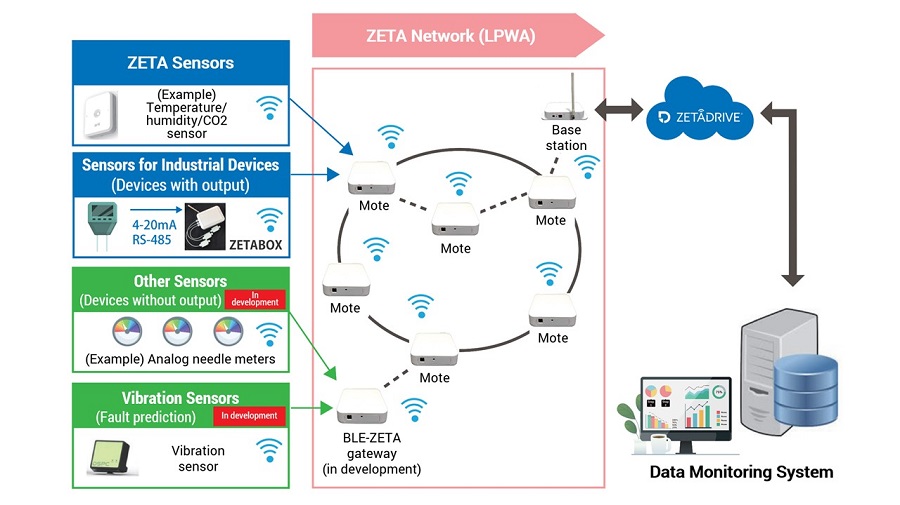

e-Platch is a packaged solution based on the automated environmental data collection system Toppan established at its own plants in October 2021. Taking advantage of ZETA,1 a next-generation Low Power Wide Area (LPWA) network protocol, Toppan created an automated system using existing measuring instruments on a blind-spot-free ZETA network and has been introducing it to its own plants. Integrated monitoring, including analysis of environmental data and generation of reports, is now possible due to the addition of an automated remote reading function for analog needle meters and a dedicated monitoring application. The system can enhance efficiency and reduce the workload for environmental conservation and inspection work at plants and facilities and enable human resources to be allocated to more active conservation activities.

e-Platch will be on display in the Toppan corner of the ZETA Alliance booth (3-6, West Hall 1) at the Local 5G/IoT Service Expo, held at the Tokyo Big Sight exhibition center from June 29 to July 1.

Efforts to tackle climate change and other global environmental issues are now essential for the survival of businesses. In light of the need to contribute to achievement of the SDGs, environmental conservation at manufacturing sites in particular is a corporate social responsibility. However, it has been difficult to take advantage of the Internet of Things (IoT) by using conventional network technologies at many plants because measurement instruments and sensors are often installed in locations indoors or underground with poor signal reception or in outdoor areas with limited access to power sources. Other challenges for leveraging the IoT include the human workload for collecting environmental data from measurement instruments or sensors and, in particular, for physically reading analog needle meters. The investment required to switch to digital meters presents another hurdle.

Toppan, backed by expertise in ZETA communication, has brought its technology and expertise to a collaboration with Alps Alpine Co., Ltd. (Alps Alpine), a company boasting advanced technical capabilities and an extensive track record in electronic components and in-vehicle information devices. The two companies have made it possible for automated remote reading devices fitted to existing analog needle meters to be used on a ZETA network.

A blind-spot-free ZETA network, data converters that make use of existing measurement instruments, and automated remote reading of analog needle meters combine to eliminate obstacles to the use of the IoT for monitoring of environmental data. In addition, integration and visualization on a dedicated application deliver an end-to-end solution for digital transformation (DX) of environmental conservation. Toppan can also provide an interface with its NAVINECT® manufacturing DX support solution via ZETADRIVE®, which collects and manages various data obtained over a ZETA network.

“e-Platch is an ideal solution for customers needing to address challenges in collecting environmental data,” said Yoshihisa Aida, General Manager of Marketing in Toppan’s Electronics Division. “We believe it provides significant value to manufacturing operations by offering innovative new ways to reduce human workload using a ZETA network that can cover every area of a plant, but without requiring existing instruments to be replaced.”

Features of e-Platch™

ZETA-based blind-spot-free wireless network

Many manufacturing plants have areas with complex structures that inhibit signal transmission or locations at which it is difficult to secure a power source. Appropriate positioning of battery-operated intermediate nodes, known as motes, makes it possible to put in place a wireless network without blind spots.

ZETABOX™ data converter facilitates use of existing measurement instruments

The ZETABOX™ data converter makes it possible to digitize data output from measurement instruments and send it to a ZETA network. Because existing measurement instruments can be used, initial costs are reduced and data collection does not necessitate changes to the way maintenance and related tasks are performed.

© Alps Alpine Co., Ltd.

The workload required to physically check multiple analog needle meters inside a plant can be reduced through automated remote reading, achieved by linking up with the IoT-based solution for analog meter monitoring developed by Alps Alpine. A ZETA-compliant system has been created by combining Toppan’s strengths in developing solutions leveraging digital technologies with Alps Alpine’s device and software capabilities.

The movement of a specially-designed magnetic holder attached to the meter needle is measured by a magnetic sensor, and the angle is communicated to a cloud server by ZETA technology. The meter values are then calculated and made visible on the dedicated application. This also makes remote monitoring of readings possible at low cost because the device can be attached to meters that are already installed. A significant advantage of this solution is the high level of accuracy it provides due to being affected little by external conditions, such as the shadows of covers or insufficient light, which can be problematic for the current camera-based techniques that are widely used.

Dedicated e-Platch monitoring application to visualize environmental conservation activities

The data collected by sensors are managed on the cloud-based ZETADRIVE platform. Through an Application Programming Interface (API) with a dedicated monitoring application, the data can then be used for analysis, graph creation, alert functions, report generation, and other outputs to provide comprehensive visibility for environmental conservation work.

Linkup with NAVINECT for manufacturing DX support

NAVINECT is Toppan’s solution for supporting digital transformation of manufacturing operations. Options for manufacturing line monitoring can be increased significantly by linking up with NAVINECT through ZETADRIVE.

NAVINECT website: https://navinect.jp/ (Japanese)

About the Local 5G/IoT Service Expo

Dates: June 29 to July 1, 2022

Times: 10:00—18:00 (10:00—17:00 on final day)

Venue: Tokyo Big Sight, West Hall 1, booth 3-6

Organizer: RX Japan Ltd.

Website: https://www.cbw-expo.jp/en-gb/about/l5g.html

About Toppan

Established in Tokyo in 1900, Toppan is a leading and diversified global provider committed to delivering sustainable, integrated solutions in fields including printing, communications, security, packaging, décor materials, electronics, and digital transformation. Toppan’s global team of more than 50,000 employees offers optimal solutions enabled by industry-leading expertise and technologies to address the diverse challenges of every business sector and society and contribute to the achievement of shared sustainability goals.

For more information, visit https://www.toppan.com/en/ or follow Toppan on LinkedIn https://www.linkedin.com/company/toppan/.