© TOPPAN INC.

Tokyo – August 17, 2023 – Toppan (TYO: 7911), a global leader in communication, security, packaging, décor materials, and electronics solutions, has installed production equipment for Catalyst Coated Membrane (CCM)/Membrane Electrode Assemblies (MEA) at its Kochi Plant in Kochi Prefecture, Japan. Aiming to enter the hydrogen energy market, Toppan is using a first-of-its-kind proprietary manufacturing method to enable mass production of high-performance, high-quality CCM/MEAs and is launching sales in August.

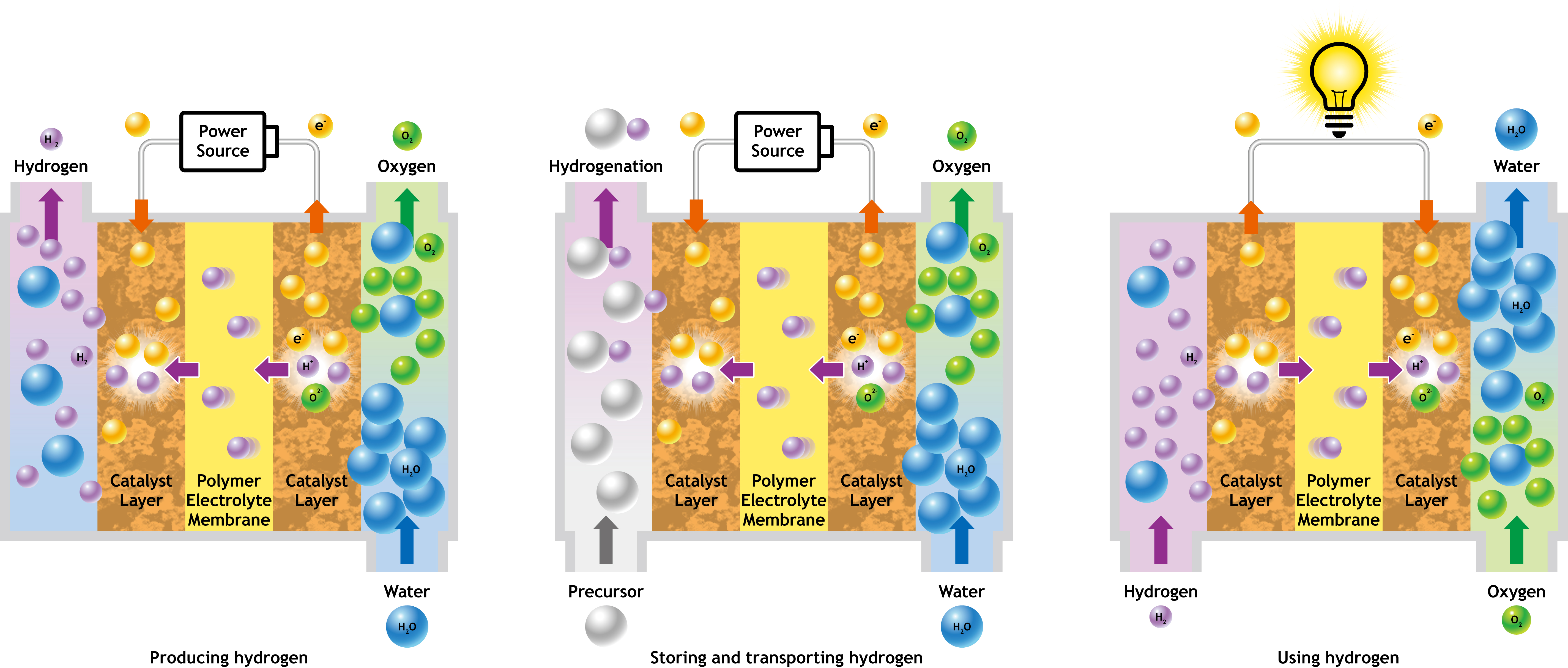

CCM/MEAs are core components of water electrolysis equipment for hydrogen production, electrolyzers related to hydrogen storage and transportation, and fuel cells that use hydrogen. As energy conversion devices, they will be essential for the creation of a hydrogen-based society in the future.

With the equipment installed, Toppan can mass produce sheet-type CCM/MEAs. This is made possible by leveraging Toppan’s manufacturing technologies, such as base sheet transfer and uniform coating on large surfaces, a technique developed in the manufacture of large color filters.

Toppan aims to help shape a hydrogen-based, carbon neutral society by rolling out CCM/MEAs in all fields related to producing, storing and transporting, and using hydrogen.

“Toppan’s original technology will enable us to mass produce high-quality CCM/MEAs and also meet the needs of each user,” said Jin Endo, Managing Executive Officer of R&D Strategy and Business Development at Toppan. “Going forward, we will scale up and bolster equipment in step with the growth of the business as we ensure a stable supply of CCM/MEAs for every application to help drive the creation of a hydrogen-based society.”

Background

Countries and regions around the world have set target figures and launched policy initiatives to achieve carbon neutrality in 2050. Japan is advancing a range of initiatives, including the use of renewable energy, efforts to establish a hydrogen-based society, and development of carbon recycling technologies. Hydrogen in particular is viewed as having significant potential as an energy source because it can be generated from water, an abundant resource, and no CO2 is emitted.

CCM/MEAs are important components for practical use of hydrogen in society. High energy conversion efficiency, durability, and stable supply to the market are required. To address these needs, Toppan began research and development on CCM/MEAs in 2004. By leveraging coating and sheet transfer technologies developed in the manufacture of large color filters, Toppan has now created a system for mass production of high-performance, high-quality sheet-type CCM/MEAs and is launching sales in August.

Features of the equipment and the CCM/MEAs manufactured

・First-of-its-kind proprietary manufacturing method enables mass production of high-output CCM/MEAs

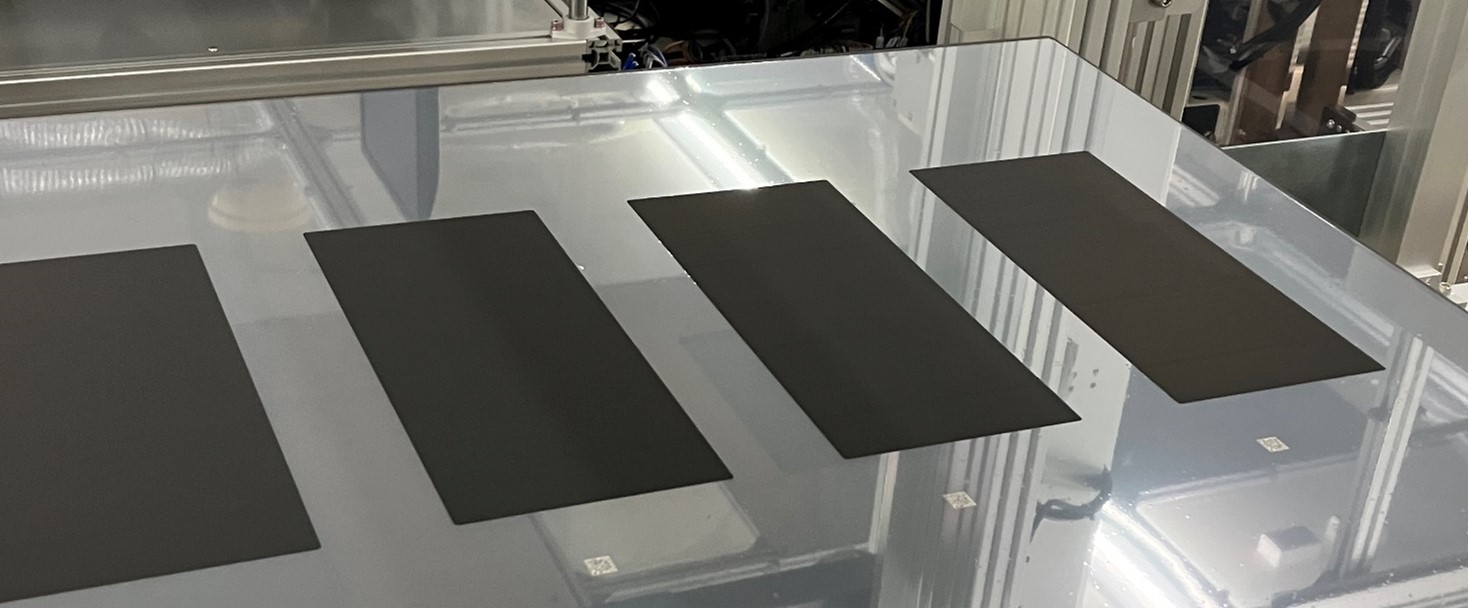

The equipment installed by Toppan employs sheet-type double-sided direct coating, a first-of-its-kind manufacturing method. Mass production is made possible by applying catalyst ink directly to both sides of the electrolyte membrane and printing the CCM/MEA on a sheet. The size of a sheet is 600 mm x 800 mm, and up to 60,000 sheets can be manufactured per year. This is equivalent to approximately 600,000 CCM/MEAs per year for fuels cells used in mobile objects such as vehicles and drones. Sheet-type CCM/MEAs can also be joined for delivery in roll form.

© TOPPAN INC.

・CCM/MEAs manufactured via direct coating can enhance energy conversion efficiency

Because the adhesion between the electrolyte membrane and catalyst layers is strong in CCM/MEAs produced by direct coating, electrical resistance is reduced during reactions when producing, storing and transporting, or using hydrogen, and energy conversion efficiency can be increased.

© TOPPAN INC.

・Proprietary additive improves CCM/MEA durability

The addition of a proprietary material makes it possible to control the porosity of catalyst layers and adjust the degree of ease with which water generated by hydrogen use can be discharged. Water accumulation causes degradation of the carbon and catalyst metal in the catalyst layer, so facilitating its discharge improves the durability of CCM/MEAs. In the case of fuel cell vehicles, electrode degradation caused by use can be suppressed, helping to extend overall travelling distance.

・CCM/MEA customization possible

Adding the proprietary material and optimizing the material design of the catalyst layer in other ways makes it possible to provide CCM/MEAs customized for each user. Toppan is offering a basic lineup of four types of CCM/MEA for fuel cells, but CCM/MEAs can also be customized to meet the user’s needs.

・Proprietary traceability system enables mass production of high-quality CCM/MEAs

Toppan has established a quality control system by taking advantage of knowledge and expertise in precision electronic component manufacturing and quality control accumulated in the color filter business. All information on materials, manufacturing history, test results, and other data related to CCM/MEA manufacture can be saved and individually tracked to facilitate stringent quality management. Toppan is also advancing development to enable analysis of accumulated data as well as full automation of process improvement (feedforward) based on the results of analysis.

Toppan’s Kochi Plant, where the new equipment has been installed, has IATF 16949 certification1 for TFT-LCDs for automobiles and implements comprehensive quality control of manufacturing processes.

About Toppan

Established in Tokyo in 1900, Toppan is a leading and diversified global provider committed to delivering sustainable, integrated solutions in fields including printing, communications, security, packaging, décor materials, electronics, and digital transformation. Toppan’s global team of more than 50,000 employees offers optimal solutions enabled by industry-leading expertise and technologies to address the diverse challenges of every business sector and society and contribute to the achievement of shared sustainability goals.

For more information, visit https://www.toppan.com/en/ or follow Toppan on LinkedIn https://www.linkedin.com/company/toppan/.