Etching of clad materials

TOPPAN has newly developed a technology to etch clad materials (Dissimilar metal material).

This technology realizes patterning of shapes that is not feasible with the conventional processing for single materials.

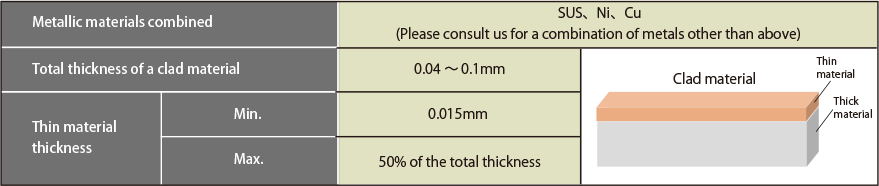

Specifications of clad-material etching

Clad materials are made by laminating metal plates of different kinds and thickness (thin and thick).

Note that dimensions and tolerances vary depending on the shape to process. Please contact us for detailed information.

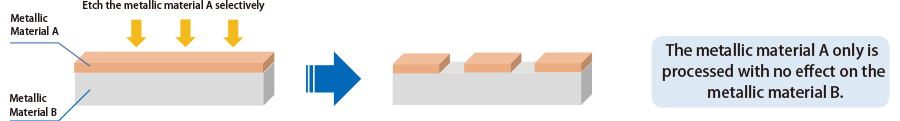

Features of clad-material etching

With a clad material, only either of two metallic plates is etched selectively. Unlike the single-metal etching enabling the isotropic processing only, the clad-material etching allows processing of anisotropic shapes.

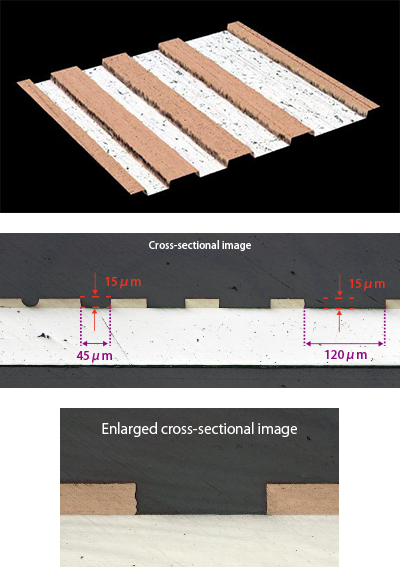

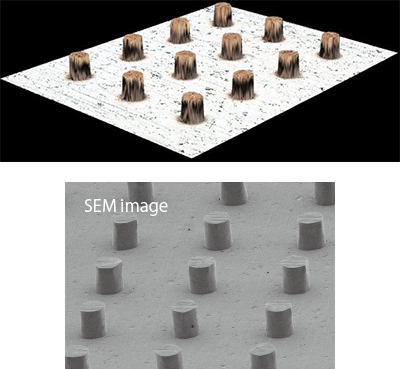

Etching example 1: Rectangular channel shape

-

Etching a clad material (Cu/SUS)

-

Etching a single metallic material (Cu)

- Openings of different widths can be processed to the same depth.

- Vertical etching is feasible.

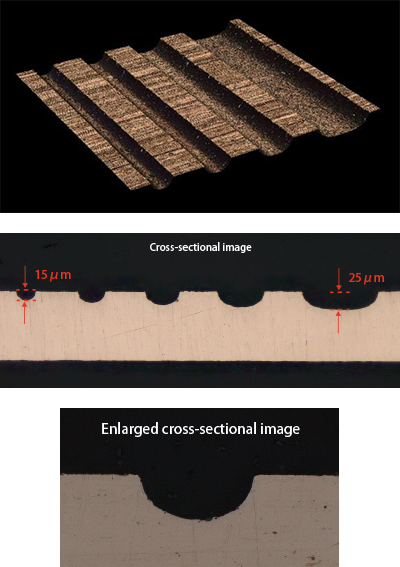

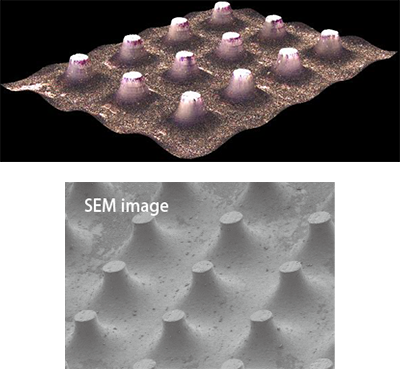

Etching example 2: Pillar shape

-

Etching a clad material (Cu/SUS)

-

Etching a single-metallic material (Cu)

- Shapes, like a pillar shape, which are difficult to process with the conventional etching, can also be processed (etched).